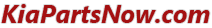

The timing system is complex, and severe engine damage will occur if mistakes are made. Only attempt this procedure if highly experienced with this type of repair; if unsure, consult an expert. Double-check all work and ensure everything is correct before starting the engine. Begin by disconnecting the cable from the negative battery terminal, loosening the lug nuts on the right front wheel, raising the vehicle securely on jackstands, and removing the right front wheel. Set the engine at TDC compression for cylinder number one, remove the right engine splash shield, and place a floor jack with a block of wood under the oil pan to take weight off the engine mounts. Remove the upper engine mount bracket, loosen the water pump pulley bolts, and remove the drivebelt. Next, remove the idler pulley and the drivebelt tensioner pulley assembly, noting that the tensioner pulley bolt has a left-hand thread. Remove the water pump pulley and the crankshaft pulley, ensuring to hold the pulley from turning while removing the bolt. Remove the engine mount bracket from the front of the timing chain cover and the valve cover. Lower the air conditioning compressor and its mounting bracket, then support the engine to remove the jack from beneath the oil pan. After securely supporting the engine, remove the oil pan. Temporarily place the crankshaft pulley onto the crankshaft to verify TDC, then remove the timing chain cover, making notes of the crankshaft key alignment and TDC marks on the camshaft sprockets. Compress the plunger of the timing chain tensioner and secure it in the retracted position with a small drill bit or steel pin before removing the tensioner. Remove the timing chain tensioner arm and lift off the timing chain, followed by the timing chain guide if necessary. Remove the chain oiling nozzle and the crankshaft sprocket, then compress and remove the balance shaft chain tensioner and its arm and guide. Unbolt and remove the balance shaft module along with the chain. Visually inspect all parts for wear and damage, checking the timing chain for any signs of wear and replacing it if necessary, along with the balance shaft chain if applicable. Check all sprockets for rough operation, grease leakage, and damage, and replace components as needed. Verify that the crankshaft hasn't turned, align the marks on the balance shaft module with the cast marks on the housing, and align the colored link of the balance shaft chain with the mark on the balance shaft module sprocket before installing the balance shaft module and tightening the bolts. Ensure the colored links of the chain align with the marks on the sprockets, then install the chain guide, tensioner arm, and tensioner, pulling the pin to allow the rod to extend. Again verify that the colored links and timing marks are aligned properly, then install the timing chain sprocket and oil spray nozzle. Check the crankshaft key alignment and verify that the camshaft sprocket marks are aligned with the top surface of the cylinder head. Install the timing chain guide and place the timing chain on with the colored links aligned with the sprocket marks, ensuring no slack exists between the sprockets. Install the tensioner arm and tensioner, pulling the pin from the tensioner. Rotate the crankshaft clockwise two complete turns by hand, stopping if any resistance is felt, as this indicates a problem. Clean all sealing surfaces of the timing cover and engine, ensuring they are free of foreign material and grease, and remove the crankshaft oil seal if intending to replace it. Apply RTV sealant where the block meets the cylinder head and around the entire timing chain cover, then set the cover in place, aligning its holes with the dowels on the block and tightening all bolts. Finally, install the crankshaft oil seal, tapping it into place with a hammer and block of wood after oiling the rubber lip, and complete the installation in reverse order of removal.

Posted by KiaPartsNow Specialist