×

- Live Chat

- 1-888-958-2959

My Garage

My Account

Cart

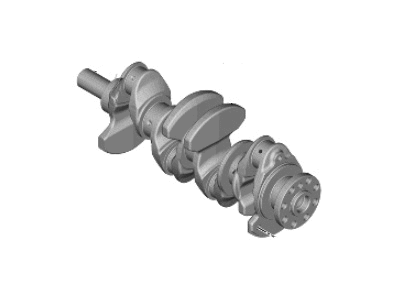

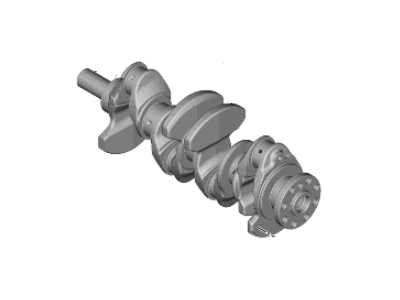

Genuine Kia Sportage Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Crankshafts found

Kia Sportage CRANKSHAFT Assembly

Part Number: 2311023710$604.17 MSRP: $864.34You Save: $260.17 (31%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT

Part Number: 2311037300$8.44 MSRP: $11.43You Save: $2.99 (27%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT Assembly

Part Number: 2311037400$8.44 MSRP: $11.43You Save: $2.99 (27%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT Assembly

Part Number: 231103E101$543.80 MSRP: $798.53You Save: $254.73 (32%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT Assembly

Part Number: 0K01511300$784.11 MSRP: $1151.42You Save: $367.31 (32%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT

Part Number: 231112S000$998.78 MSRP: $1428.87You Save: $430.09 (31%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT

Part Number: 343L62SK00$973.06 MSRP: $1428.87You Save: $455.81 (32%)Ships in 1-3 Business DaysKia Sportage CRANKSHAFT

Part Number: 695G62MH00$1106.63 MSRP: $1625.00You Save: $518.37 (32%)Ships in 1-3 Business Days

Kia Sportage Crankshaft

If you're in search of top-notch, reasonably priced OEM Kia Sportage Crankshaft, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sportage Crankshaft, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sportage Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed from the engine after it has been taken out of the vehicle on Kia Sportage?A: The crankshaft has to be removed with the engine extracted from the car, provided it is free of such parts as the flywheel, crankshaft pulley, timing belt or chain, oil pan, oil pump body, oil filter as well as piston/con-rod assemblies. Before the puller is applied, one needs to check the end play of the crankshaft by setting a dial indicator to the crankshaft and observing the distance that it moves back and forward when the crankshaft is pricked to the rear and then forward. End play is usually between 0.003 and 0.010 inches (.076 and 0.254 mm); if it is higher, check the thrust faces for wear. As we mentioned earlier, when a dial indicator in not available feeler gauges can also be used measure clearance. Leverage the cap of main bearings and undertake the following processes, you have to tighten them in a gradual manner in order to remove them, however before doing so new bolts should replace the old ones in instances where they are used. Lift off the main caps as well as the thrust bearing caps and carefully lift the crankshaft off, preferably with help since they are usually very heavy. For installation, be sure that engine block and crank main are clean and examinated. Align the block with its bot tom upwards to remove any contaminants and take out the original bearing inserts; the mating surfaces should be cleaned. New upper main bearing inserts must be pressed into the main bearing journals; check that oil hole is matched with the others before inserting the lower inserts into the main bearing caps. Care should be taken not to mar the inserts and similarly there should be no application of lubrication at this point. Before laying the crankshaft, ensure the oil holes in the crankshaft are clean. To measure main bearing oil clearance, you should apply Plastigage to each journal, place the main bearing caps as they should be without shifting the Plastigage, then, and finally, tighten the bolts in the right manner. Upon taking out the caps, measure the Wmax of the crushed Plastigage and look on the scale to check the clearance, making sure no contaminants are on it. If clearance is incorrect, measure the bearings inserts diameters, and look for tapering on the crankshaft journal. Wipe off any Plastigage deposits on the journals and insert faces and apply a layer of moly-base grease or engine assembly lube on the bearings before replacing the crankshaft. It should be noted that all mating surfaces must be kept clean and free of oil, fresh engine oil must be applied to new bolt threads and tightened to the required torque, but no less. Check the crankshaft end float again and turn the crankshaft it should rotate smoothly and if not free the crankshaft, components or any other pulley that is causing binding. Last of all, fit the new rear main oil seal as well.

Related Kia Sportage Parts

Browse by Year

2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft